Testing Service

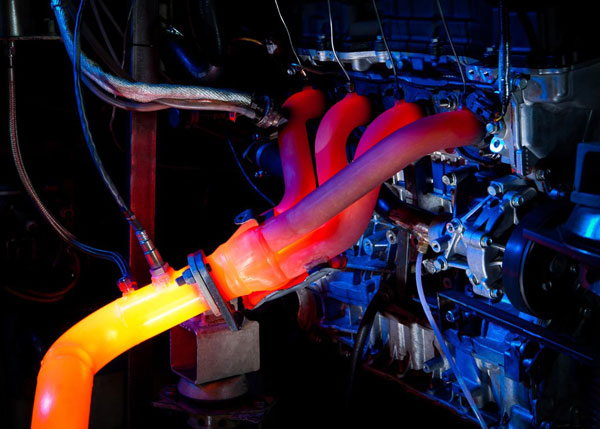

Against the background of increasing challenges due to stricter emission legislations and more complex powertrain systems we have modernised our testing area. With our facilities we now offer all testing services for system and component testing as well as complete powertrain testing.

To fulfil the customer requirements, we are able to adapt our test benches individually and provide the specific measurement equipment according the specific development tasks. Qualified engineers and technicians supervise all test runs at the test benches.

In cooperation with our engineering partners, we also offer individually configured test bench solutions for our customers, which meet state of the art testing requirements.

Powertrain Testing

Our portfolio covers the range of transient, hybrid, powertrain and vehicle test benches with full media conditioning and full flow measurement possibilities. Test parameters include for example power and torque measurements, fuel measurement, electric power measurement, battery simulation, emission measurement (gaseous, PM, PN), blow-by measurement, and cylinder pressure indication.

In order to shorten development times – especially in technology-oriented development projects – our engineers are joining the test bench work. Thus, already during the measurement procedure, they can interpret the results and derive immediate next steps.

Tests we offer:

- Conventional and hybrid powertrain testing

- EV testing

- Mechanical and functional testing

- Performance and durability tests

To ensure that your products comply with the requirements of the regions you would like to access, we offer testing solutions due to the following global standards:

- WLTP

- RDE

Test Bench Solutions

A team of experts from our testing facility area and high-skilled engineers from our thermodynamic and mechanical department together with our engineering partners is available to configure your individual test bench solution.

Our portfolio covers the range of standard 1-axle engine test benches up to full 5-axle powertrain test benches, on demand equipped with

Component Testing

On our mechanical test rigs, equipped with state-of-the-art measurement technology, a towing capacity of up to 65 kW, and media conditioning, we examine all the engine components and assemblies. By means of contacting and contactless measurement techniques and fast signal acquisition systems, we are testing